WIRE FEEDERS

Wire feeders allow you to save money on the alloy you use to braze your parts. They also save operator time installing paste or preforms. Our systems include the important controls necessary to make the process run smoothly..

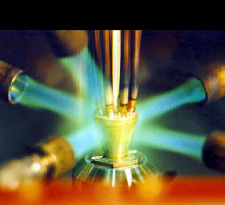

GAS FLUX

GAS SYSTEMS AND INDUCTION

How you heat the parts can make all the difference. Gas systems can be air/fuel or oxy/fuel. Induction power supplies come in a variety of frequencies depending on the materials being brazed. Call us today to help pick which heating type is best for your parts.

SERVICE AND SUPPORT

You don't want a machine, you want a process that will lower your labor costs, increase production, improve quality and enhance safety. Without service and support from your machine suppier you can be left with a machine that no one understands. We are always available to be sure your machine doesn't collect dust. We are free on the phone, can be on your plant floor fast, and speak your language.

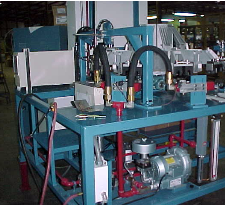

Single and Dual Cell Brazers

Single and dual cell brazers often are all that is necessary to optimize your brazing process

They take the guess work out of heating, cooling and can automatically apply flux and wire feed to free up the operators time to handle and inspect. With a dual cell, production can be doubled with the same operator.

For a quote, all we need are your part prints or pictures and the quantity of parts you need to produce in a given time. We can even ballpark your project right over the phone.

We can add gas flux to our brazers. In some cases gas flux can be used to replace paste flux. This process will eliminate the need for post cleaning on copper and brass parts and can allow the parts to go straight to the assembly line after brazing.